The implementation of nanosensors within the field would present itself as a challenge for surveillance workflows, and would require considerable effort for integration within data analytics systems. The technology would be aided by other concepts as well such as AI and Cognitive systems, which have historically been used in seismic processing rather than other O&G domains. Today, cognitive approach has gained widespread acceptance, thanks to recent breakthroughs, and is found in diagnostic systems within the fields of electronics, medicine, etc.

Similarly, data-driven cognitive technologies have great potential to be implemented within DOF systems. The first hurdle is a technological one, and involves storing and mining the right amount of information at an economical level. In addition, the systems that need to be developed would have to incorporate experiential learning based on years of success & failure data. The technology isn’t entirely new, and present in mechanical manufacturing where mechanisms are in place to capture & learn from failures. But DOFs require a high degree of sophistication to be dealt with, given the uncertainty that lies within hydrocarbon reservoirs, and other parameters that need to be considered.

There is a wonderful opportunity in linking the step change in data acquisition in the DOF era with data-driven workflows. It is therefore vital that high-level problems be viewed so that the bottlenecks can be put in perspective, allowing maximum opportunities to be captured. Modern practices do allow social behaviors to be monitored, and even work in a predictive manner but understanding the interpretation of these functionalities still requires a lot of effort.

It must be realized that the technological industrial revolution is here, and as hardware costs continue to go down, all types of companies would begin to go to “smart”. Even small operators would make use of their data, and apply analytics on them. Soon enough, analytics would move towards edge devices such as sensors, so that data wouldn’t have to managed altogether, and a completely self-service system can be developed. If the demographics of the younger populace are studied, it can be instantly inferred that to them technology is everything, serving functions such as communication, logistics and socialization.

Similarly, is there a potential for cutting-edge mobile technology to synergize with O&G optimization, and how could going digital save costs? While concepts of data science have been floating around for decades, they have seldom been applied so readily as they are today, primarily due to the availability of data. A significant credit also goes to the availability of greater compute power, especially access to the cloud which has made it extremely easy to work with high-end algorithms. A perfect example to this advancement is the recent defeat of reigning GO champion by Google’s DeepMind team, which didn’t rely on brute-force techniques but on oceans of data, large clusters of GPU and deep-learning neural networks. And while the O&G industry is lagging on acceptance of this technology, there has been an appreciate surge in use of data science in oil field operations.

Wireless Technology

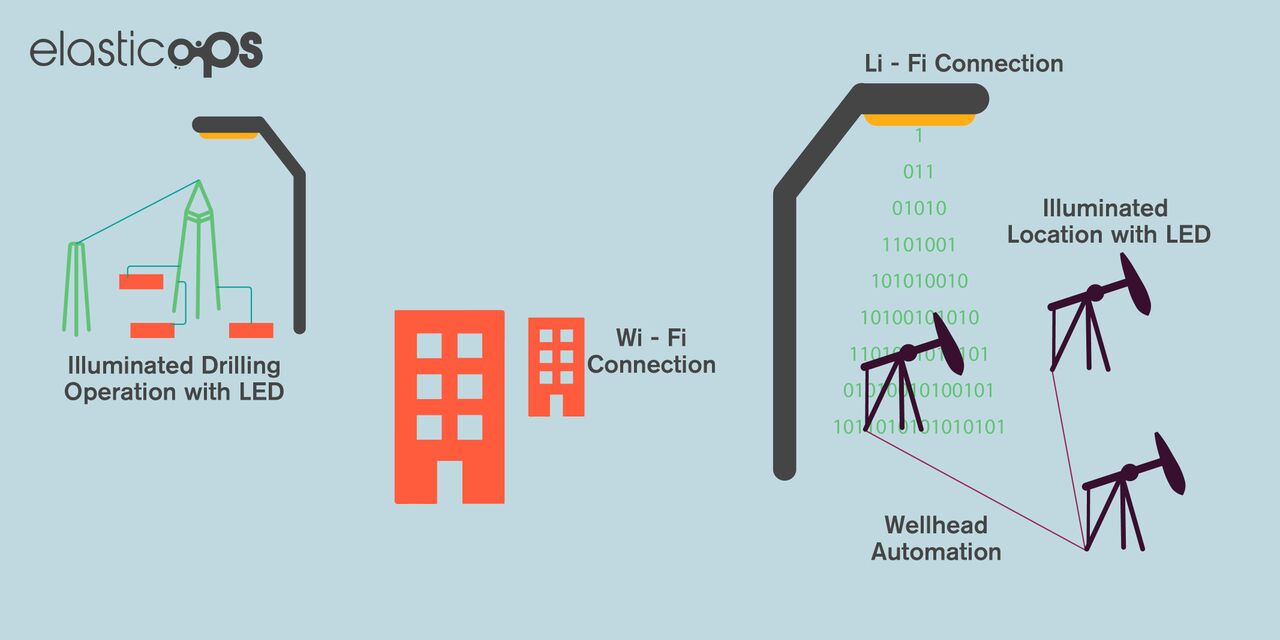

The widespread acceptance of automation & control technology powered by AI and data science won’t be possible without the use of communication technologies with higher bandwidths. Wi-Fi is a vital part of this equation as the swathes covered by an oilfield can only be served economically if a wireless medium is used. One promising technology is Li-Fi that makes use of LEDs to transmit data, the illustration for which is given below:

Li-Fi was created in the University of Edinburg in 2011, and tests have revealed that it is 10,000 times the frequency spectrum of radio waves, achieving data transmission rates of up to 10 Gbps. In comparison, Wi-Fi peaks out at 2 Gbps. While Li-Fi’s inability to penetrate solid objects is seen as a downside, it also means greater security as signals can’t be sniffed outside a particular physical enclosure. Other problems exist as well such as its reliance on a constant and reliable source of electricity, but as the invention is still in its early stages, these problems are expected to fade away with time. The final solution would have to incorporate a hybrid of both Li-Fi and Wi-Fi. For instance, Li-Fi can be used to transmit data from well locations during the night, while Wi-Fi can be relied on during the day.

Drones

Drones are new to the O&G arena, but they present a huge potential to reduce operational costs. Their ever increasing feature-set, such as HD cameras, laser-based sensors, radar systems, etc. make them perfect for use on a large oilfield with multiple well sites. In addition, drones can be used for data collection purposes, which can then be analyzed and acted upon. All in all, they can be used for:

- Visualize field operations and audit safety conditions

- Survey far-flung areas that require considerable time to get by road

- Survey hostile environments to check the operability of wells

- Patrol for intruders

- Develop high-resolutions maps containing thermal data and digital points for greater understanding of the field

Larger drones can even be used to help with supply chain operations, carrying equipment to and from warehouses to designated areas.

Is your appetite for all things oilfield automation and production monitoring insatiable like ours? :grinning: If so, check out these related articles, The Future of Digital Oil Fields is in the hands of Industrial IoT, IoT in Oil and Gas will be Studded with Analytics in the Years to Come, The Prospects of Virtual Reality, Artificial Reality and Machine-Human Interfacing within Digital Oil Fields– they’ll be sure to pump you up!!!